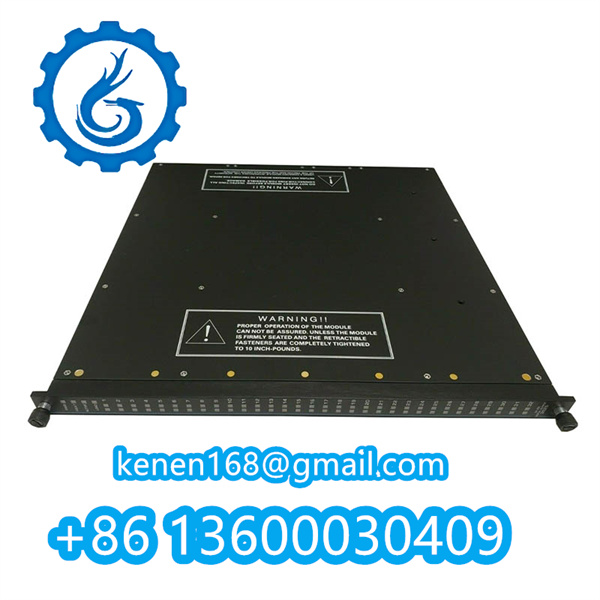

Foxboro IDP10 Series Transmitter Installation

Pre-Installation Requirements

-

Environmental Verification

- Temperature Range: -40°C to +85°C (process) / -30°C to +70°C (electronics)

- Ambient Humidity: ≤95% non-condensing

- Atmospheric Compatibility: NACE MR0175/ISO 15156

-

Process Interface

plaintextCopy Code- Flange Standard: ASME B16.5 Class 300 RF

- Material: 316L SST w/ Hastelloy C-276 diaphragm

- Seal Options: FKM (Standard) / FFKM (Aqueous HCl)

Mechanical Installation Procedure

Step 1: Mounting Configuration

plaintextCopy Code

[Remote Seal Assembly]

1. Install capillary assembly with minimum bend radius R≥75mm

2. Orientation:

• Horizontal pipes: Sensor at 4 or 8 o'clock position

• Vertical pipes: Flow direction → HP port

3. Support capillary every 300mm (use P-clamps CAT #FXB-SUPP-10)

[Torque Specifications]

• Flange bolts: 45 Nm ±5% (crisscross pattern)

• Process connectors: 35 Nm (DN20) / 55 Nm (DN50)

Step 2: Pressure Balancing

CRITICAL ACTIONS

- Equalize static pressure before power-up

- Bleed air via vent screws (clockwise to close)

- Confirm zero differential at startup

Electrical Installation

plaintextCopy Code

[Wiring Diagram]

Terminal + ───[24V PSU]───[250Ω Resistor]───[DCS AI]

Terminal - ────────────────────────────────────────

[Requirements]

• Cable: BELDEN 9501 (shielded twisted pair)

• Conductor: ≥1.5mm² (16 AWG)

• Intrinsic Safety: Use Foxboro ISB07 Barrier (EEx ia)

• Grounding: <1Ω to plant earth (terminal TB1)

Terminal Connections

| Terminal | Function | Wire Color |

|---|---|---|

| + | Power Supply (18-36V DC) | Brown |

| – | Signal Return | Blue |

| G | Ground Screw | Green/Yellow |

Commissioning Sequence

-

Leak Test

- Pressurize to 110% of range limit

- Acceptable decay: ≤0.1% FS/hour

-

Zero Calibration

plaintextCopy Codea. Vent both HP/LP ports to atmosphere

b. Using HART 475: Device Setup → Trim → Sensor Trim → Zero Trim

c. Confirm output: 4.00mA ±0.02mA -

Damping Adjustment

- Default: 0.4s (adjust via HART PD 1.3.4)

- Turbulent flow recommendation: 2.5-5s

Safety & Compliance

plaintextCopy Code

EX Protection: ATEX II 1G Ex ia IIC T6 Ga

Certification: IECEx UL 17.0075X

EMC: EN 61326-1 (Industrial Immunity Level)

WARNINGS

- Never apply voltage during capacitance check (damages EEPROM)

- Avoid mounting near sources of >100V/m EMI

- Seal conduits with Foxboro CPT-32 compound

Diagnostic Indicators

| LED State | Condition | Action |

|---|---|---|

| Green solid | Normal operation | None |

| Yellow flashing (1Hz) | Communication active | HART session in progress |

| Red solid | Sensor fault (ERR 38) | Check diaphragm fill |

| Off | Power loss | Verify loop resistance |

Loop Check:

Measure resistance: + to – terminals = 28Ω ±3Ω @25°C

P0500RY FOXBORO pdf

··········································································································

Our advantages:

1. The brand new product comes with a one-year

comprehensive warranty.

2. All products undergo strict quality inspections.

3. Contact us and our team will provide competitive

quotes and procurement plans.

Reviews

Clear filtersThere are no reviews yet.