1. Pre-Operation Preparation

1.1 Safety Verification

- Confirm power supply disconnection before installation

- Verify grounding resistance ≤4Ω using a megohmmeter

- Check ambient temperature (-20°C to +60℃) and humidity (<85% RH) compliance

1.2 Hardware Configuration

- Signal Wiring:

Analog Input: 4-20mA (max 250Ω load) / 0-10V (impedance ≥1MΩ) Digital Interface: RS-485 terminals (A+/B-) for Modbus RTU - DIP Switch Settings:

- SW1: HART protocol enable/disable

- SW2: Channel isolation mode (single/dual)

2. Commissioning Procedure

2.1 Power-Up Sequence

- Apply 24V DC power (18-36V range)

- Observe STATUS LED:

- Solid green: Normal operation

- Flashing red: Configuration error

2.2 Software Configuration

- Parameter Initialization:

a. Connect to ABB Control Builder via USB/RS-485 b. Import device description file (DDF) for HART/Modbus mapping c. Set scaling coefficients (e.g., 4mA=0%, 20mA=100%) - Diagnostic Test:

- Force input range violation to trigger alarm relay (NC→NO transition)

3. Runtime Monitoring

3.1 Signal Validation

- Use multimeter to verify output deviation ≤±0.1% FS

- Monitor communication errors via Modbus exception codes (e.g., 0x04 = input failure)

3.2 Maintenance Actions

| Symptom | Corrective Measure |

|---|---|

| Signal drift | Recalibrate zero/span using trim pots |

| Communication loss | Check termination resistors (120Ω) |

| Over-temperature | Verify cooling airflow ≥0.5m/s |

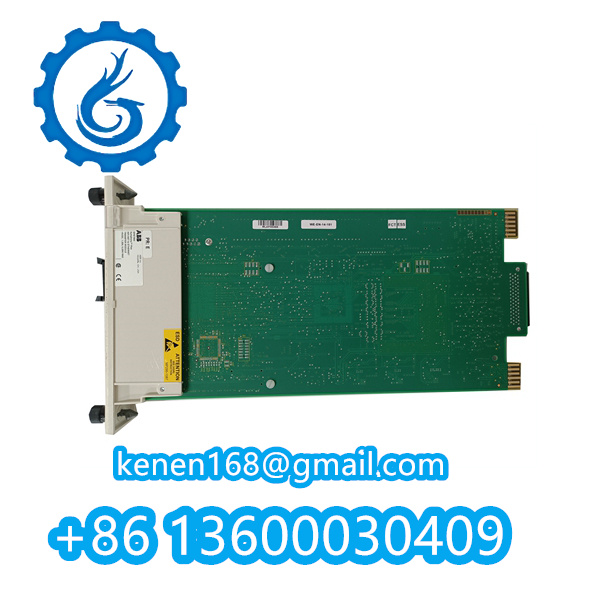

INNPM22 ABB PDF

INNPM22 ABB PDF

·········································································································

Reviews

Clear filtersThere are no reviews yet.